电机匀速转矩计算?

一、电机匀速转矩计算?

电机扭矩计算公式是T=9549 p/n。T是扭矩,单位N.m,P是输岀功率,单位kw,n是电机转速,单位r/min。

二、风力发电机匀速原理?

发电量稳定的多风向匀速风力发电机。在立轴上部有多个风勺,在铁塔架上有至少两个上口小、下口大的风筒,与风筒相应位置的立轴上固定有风扇,立轴通过一组转向齿轮与第一加力器的输入端齿轮上的轴连接,第一加力器输出端的齿轮与发条轮啮合,发条轮的输出轴通过齿轮传动机构与第二加力器、加速器、固定在地面上的发电机依次连接。

三、低速匀速控制用什么电机伺服电机可以?

用步进电机。

1)、如载荷稳定,特别是力较大且无大的波动,低速情况选用步进电机更好(结合导程细分),并且价格相对还能低一点;

2)、受力不稳,或波动范围较大,虽速度低也宜选用伺服电机,目前伺服电机价格已大幅下降至跟步进电机差距不太大了。 综述,步进电机细分能达到所述要求,如为1的情况,步进电机的工作特征更符合。(目前有一种盲目推崇伺服电机的风气,实则需根据使用情况定,而不是根据所谓“档次”)

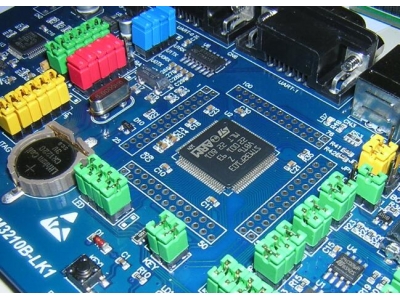

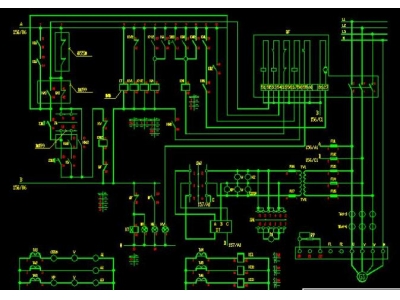

四、电机复位电路?

电机复位,是这样理解,在电机主电路中有一个热继电器(过载保护),当电机过载时,热继电器动作,常闭触点切断控制电路,常开触点闭合接通指示灯。

过载排除后,热继电器的触点有两种复位方式使电路重新开始工作:

1、手动复位——需要按下复位按钮;

2、自动复位——过载去除,等一会儿,它冷却后自动恢复正常。

若处在手动复位位置,找到热继电器后,按下上面的红色手柄,能听到“啪”的一声即可。电机过载主要有以下症状:

1、电机发热量增大;

2、电机转速下降,甚至可能下降到零;

3、电机有低鸣声,振动一般;

4、如果负载剧烈变化,会出现电机转速忽高忽低;电机过载产生的原因:

1、电气原因:如缺相、电压超出允许值等;

2、机械原因:如过大的转矩、电动机损坏(轴承的振动)等;

五、匀速电机转速不稳怎么回事?

(1)励磁绕组短路,主磁通减少,电动机转速上升。

(2)励磁绕组断路,只有剩磁通,电机转速剧升,有飞车危 险。

(3)负载过大使电机转速下降。

(4)电枢电路各连接点导电不良,使电枢电路压降过大,电机转速下降。

(5)检修时疏忽将个别主磁极极性接反,削弱了 主磁通,使电机转速上升。

(6)电刷不在中性线上,使电机转速不稳定。

六、伺服电机加速到匀速扭矩变化?

伺服进行扭矩控制,有一种就是当扭力越来越大,伺服速度越来越慢,还有一种是扭力越大伺服速度越来越快,当达到设定扭力时保持速度。

有两种负载用扭矩控制,一种是当速度越快扭力越大,这时采用扭力控制的话是不是会自动降低速度来把输出扭力降为设定的扭力;还有一种是速度越快扭力越小,这时采用扭力控制的话是不是会自动加快速度把扭力降为设定的扭力。

七、匀速压缩弹簧

匀速压缩弹簧:了解其原理和应用

匀速压缩弹簧是一种常见的弹簧类型,广泛应用于许多机械和工程领域。它具有稳定的弹性特性,能够在受力时提供均匀的压缩力。本文将介绍匀速压缩弹簧的原理、结构以及各种应用。

原理

匀速压缩弹簧的原理是基于胡克定律。根据胡克定律,当弹簧受到一定的力并发生压缩时,它的形变与受力成正比。而匀速压缩弹簧则能够提供一个均匀的压缩力,使得弹簧在受力过程中保持稳定的形变。

弹簧的刚度决定了其在受力时的变形程度。匀速压缩弹簧通常具有相对较高的刚度,以确保其在承受压力时始终保持稳定的形状。此外,弹簧的材料选择和尺寸也会影响其刚度和弹性特性。

结构

匀速压缩弹簧的结构相对简单,通常由高强度和耐腐蚀性能的钢线制成。在制造过程中,弹簧线会通过特殊的机械设备进行卷绕和压缩,以达到所需的形状和尺寸。

弹簧的结构设计也会根据具体的应用需求进行调整。例如,某些匀速压缩弹簧可能具有多个螺旋圈,以增加其弹性特性和承载能力。而其他类型的弹簧可能采用不同的形状,如锥形或变径设计,以适应不同的力学需求。

应用

匀速压缩弹簧在许多机械和工程领域都有广泛应用。下面是一些常见的应用领域:

- 汽车行业: 匀速压缩弹簧用于汽车悬挂系统和减震器中,能够提供稳定的压缩力,以减少车辆颠簸和提供更舒适的驾驶体验。

- 工业机械:在各种机器和设备中,匀速压缩弹簧可用于控制和调节压力、平衡力量、减震和缓冲等方面。

- 家居用品:柔软的匀速压缩弹簧可用于床垫、沙发和椅子等家居用品,提供舒适的支撑和减震效果。

- 玩具制造:匀速压缩弹簧常用于玩具中,如弹簧动物和弹簧发条玩具,为玩具增添趣味性和动态效果。

总结

匀速压缩弹簧是一种具有稳定弹性特性的弹簧类型。它适用于各种机械和工程应用,能够提供均匀的压缩力并保持稳定的形变。通过了解匀速压缩弹簧的原理和结构,我们可以更好地应用它们于实际工程和设计中。

Whether you are a mechanical engineer, an automotive enthusiast, or a hobbyist tinkering with various machines, understanding the principles and applications of the "匀速压缩弹簧" (constant force compression spring) can be invaluable. This type of spring is widely used in many mechanical and engineering fields for its stable elastic characteristics and ability to provide uniform compressive force. In this blog post, we will delve into the principles, structure, and applications of the constant force compression spring.原理 (Principle)

A constant force compression spring operates based on Hooke's law. According to Hooke's law, the deformation of a spring is directly proportional to the force applied to it when compressed. A constant force compression spring is designed to deliver a consistent compressive force, ensuring that the spring maintains a stable deformation throughout the force application. The stiffness of a spring determines the extent of its deformation under load. Constant force compression springs typically have relatively high stiffness to ensure they maintain their shape when subjected to pressure. Additionally, the choice of material and dimensions of the spring can influence its stiffness and elastic characteristics.结构 (Structure)

Constant force compression springs have a relatively simple structure, commonly made from high-strength steel wire with excellent corrosion resistance properties. During the manufacturing process, the spring wire undergoes specialized winding and compression techniques to achieve the desired shape and size. The structural design of the spring can also be modified to meet specific application requirements. For instance, some constant force compression springs may feature multiple coils to enhance their elastic properties and load-bearing capacity. On the other hand, other springs may adopt different shapes such as conical or variable diameter designs to accommodate various mechanical needs.应用 (Applications)

Constant force compression springs find widespread applications in different mechanical and engineering domains. Here are some common application areas where these springs are utilized:- Automotive Industry: Constant force compression springs are used in vehicle suspension systems and shock absorbers to provide stable compressive forces, reducing vehicle vibrations and enhancing driving comfort.

- Industrial Machinery: In various machines and equipment, constant force compression springs are employed for controlling and regulating pressure, balancing forces, and providing damping and buffering effects.

- Household Items: Flexible constant force compression springs can be found in mattresses, sofas, chairs, and other furniture items, offering comfortable support and shock-absorbing properties.

- Toy Manufacturing: Constant force compression springs are commonly incorporated into toys such as spring animals and wind-up toys, adding an element of fun and dynamic movement.

总结 (Conclusion)

Constant force compression springs are a type of spring that exhibits stable elastic characteristics. They are applicable in various mechanical and engineering contexts, providing uniform compressive forces while maintaining consistent deformation patterns. By understanding the principles and structure of constant force compression springs, we can make better use of them in practical engineering and design applications.八、电机启动到匀速转动的时间?

电机启动到匀速转动的时