a3120光耦工作原理?

一、a3120光耦工作原理?

输入是2-3脚,功能与普通的光耦一样,只是速度上高一点

输出是6-7脚,驱动IGBT比较适合,里面是集成电路,电流稍微比普通光耦电流大一些,所以它上下(VCC,VEE)是适合宽电压

其实就是说它的驱动能力强,带保护,宽电压,适合高频率,耐压高,适合IGBT

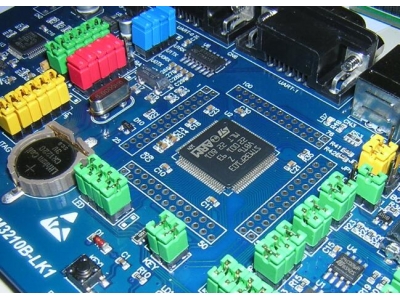

二、a3120引脚参数?

引脚参数输出电压24v

a3120引脚又叫管脚,英文叫Pin。就是从集成电路(芯片)内部电路引出与外围电路的接线,所有的引脚就构成了这块芯片的接口。引线末端的一段,通过软钎焊使这一段与印制板上的焊盘共同形成焊点。引脚可划分为脚跟(bottom)、脚趾(toe)、脚侧(side)等部分

三、a3120光耦如何测试好坏?

根据光耦内部的结构,可以用两个万用表来测量其好坏,就是在内部发光管引脚处接一机械表,黑笔接内部发光二极管的阳极,红笔接阴极。当接好后,另两脚用万表表测量应是导能的,当那机械表断开,则它又截止了。这只能大概测一下光耦的好坏,最好还是用替换法来区别好坏。

四、a3120和tlp250的区别?

A3120:输入IF电流阀值2.5mA,电源电压15∽30V,输出电流±2A,隔离电压1414V,可直接驱动150A/1200V的IGBT模块。

TLP250:输入IF电流阀值5mA,电源电压10∽35V,输出电流±0.5A,隔离电压2500V,开通/关断时间(tPLH/ tPHL)0.5μs。可直接驱动50A1200V的IGBT模块,在小功率变频器驱动电路中,和早期变频器产品中被普遍采用

2种驱动IC的引脚功能基本一致,小功率机型中可用TLP250直接代换A3120,虽然它们的个别参数和内部电路有所差异,如TPL250的电流输出能力较低,但在变频器中功率机型中,驱动IC往往有后置放大器,对驱动IC的电流输出能力就不是太挑剔了。

五、怎么量A3120光耦的好坏?

根据光耦内部的结构,可以用两个万用表来测量其好坏,就是在内部发光管引脚处接一机械表,黑笔接内部发光二极管的阳极,红笔接阴极。当接好后,另两脚用万表表测量应是导能的,当那机械表断开,则它又截止了。这只能大概测一下光耦的好坏,最好还是用替换法来区别好坏。

六、a3120引脚图及功能?

a3120是一种光耦隔离器件,其引脚图如下

1. VCC正电源输入

2. GND负电源输入

3. VO输出信号

4. VI输入信号

a3120的功能是将输入信号通过光耦隔离后输出,可以实现电路隔离和信号传输的目的。其原理是通过光电转换将输入信号转换为光信号,再通过光耦隔离器件将光信号传输到输出端,再通过光电转换将光信号转换为输出信号。

七、a3120可以用什么光耦代替?

50A以下的的IGBT驱动可以代替使用。3150的驱动电流是0.5A,3120的是2.5A

A3120是安华高的 HCPL-3120 ,最大输出电流为2ATLP350为东芝的,最大输出电流我2.5A差别不是很大,可以替换

我有一台三菱变频器,驱动用的是tlp251,坏了,但我手头只有a3120,

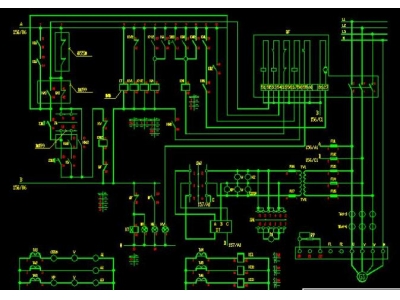

八、电路图?

画电路图需要先找好图形绘制工具 与工具相结合 能更快 更好的提高工作效率 不耽误时间 现在市场上的亿图图示功能很强大 操作简单

九、光耦a3150v可用a3120代吗?

50A以下的的IGBT驱动可以代替使用。

3150的驱动电流是0.5A,3120的是2.5A

十、探照灯电路图

探照灯电路图: 理解、构建和优化探照灯

探照灯是一种广泛应用于舞台演出、户外照明和应急照明等领域的强光照明设备。在探照灯的核心部件之一是它的电路板,负责控制和供电。本文将带您深入了解探照灯电路图的构建和优化,帮助您了解探照灯的工作原理,并提供指导以构建高效可靠的探照灯。

了解探照灯电路图

探照灯电路图通常包括多个关键组件,如电源模块、控制模块、光源模块等。通过仔细研究电路图,您可以了解到这些组件之间的连接方式和信号传输原理。

在电路图中,常见的连接方式包括并联和串联。并联的组件同时接收相同的电压,但电流被分流到各个组件;串联的组件则依次接收电压,电流在各个元件之间相等。

此外,探照灯电路图中的控制模块通常包括变阻器、电位器和开关等元件,用于调节和控制亮度、色温等参数。

构建探照灯电路图

构建探照灯电路图需要具备一定的电子电路基础知识。以下是构建探照灯电路图的基本步骤:

- 确定探照灯的功率需求和光照要求。

- 选择合适的电源模块,确保其输出电压和电流满足探照灯的需求。

- 设计控制模块,包括亮度调节、开关控制和保护电路。

- 选择合适的光源模块,如LED光源。

- 根据电路图进行元件的连接和布局。

- 进行电路测试和参数调整,确保探照灯的性能符合要求。

优化探照灯电路图

优化探照灯电路图可以提高探照灯的性能和稳定性,延长其使用寿命。以下是一些优化措施:

- 选择高效能源: 选择高效的电源模块,以减少能量损耗和发热。

- 合理布局: 在电路板上合理布局组件,减少信号干扰和高温区域。

- 保护电路设计: 添加过流保护、过压保护和短路保护等保护电路,提高探照灯的安全性。

- 使用优质材料: 选择优质元件和材料,降低故障率和损耗。

- 热管理: 针对高功率探照灯,设计风扇散热模块,保持其正常工作温度。

结论

探照灯电路图是构建和优化探照灯的重要参考。通过深入了解电路图,您可以更好地理解探照灯的工作原理,并根据需求构建高效可靠的探照灯。优化探照灯电路图可以提高探照灯的性能和稳定性,延长其使用寿命。希望本文对您进一步了解和构建探照灯有所帮助。

Translated text in English: htmlFlashlight Circuit Diagram: Understanding, Building, and Optimizing Flashlights

A flashlight is a powerful lighting device widely used in stage performances, outdoor lighting, and emergency illumination. One of the key components of a flashlight is its circuit board, which is responsible for control and power supply. This article will take you through the understanding, building, and optimization of flashlight circuit diagrams, helping you grasp the working principles and provide guidance for constructing efficient and reliable flashlights.

Understanding Flashlight Circuit Diagrams

A flashlight circuit diagram typically consists of several essential components such as power modules, control modules, and light source modules. By studying the circuit diagram closely, you can understand how these components are connected and the principles of signal transmission.

In circuit diagrams, common connection methods include parallel and series connections. In parallel, the components receive the same voltage simultaneously, but the current is divided between them. In series, the components receive the voltage sequentially, and the current is equal between the elements.

In addition, the control module in the flashlight circuit diagram often includes components such as variable resistors, potentiometers, and switches to regulate and control brightness, color temperature, and other parameters.

Building Flashlight Circuit Diagrams

Building a flashlight circuit diagram requires a certain level of knowledge in electronic circuits. The following are the basic steps for constructing a flashlight circuit diagram:

- Determine the power requirements and lighting needs of the flashlight.

- Select a suitable power module to ensure its output voltage and current meet the requirements of the flashlight.

- Design the control module, including brightness adjustment, switch control, and protection circuits.

- Select a suitable light source module, such as LED light sources.

- Connect and layout the components according to the circuit diagram.

- Conduct circuit testing and parameter adjustment to ensure the flashlight's performance meets the requirements.

Optimizing Flashlight Circuit Diagrams

Optimizing flashlight circuit diagrams can improve the performance, stability, and longevity of flashlights. Here are some optimization measures:

- Choose efficient power sources: Select high-efficiency power modules to reduce energy loss and heat generation.

- Proper layout: Arrange components on the circuit board in a manner that reduces signal interference and high-temperature areas.

- Protection circuit design: Add protection circuits such as overcurrent protection, overvoltage protection, and short circuit protection to enhance flashlight safety.

- Use high-quality materials: Choose quality components and materials to lower failure rates and losses.

- Thermal management: Design fan cooling modules for high-power flashlights to maintain normal operating temperatures.

Conclusion

A flashlight circuit diagram is a crucial reference for building and optimizing flashlights. By gaining a deeper understanding of the circuit diagram, you can better comprehend the working principles of flashlights and construct efficient and reliable flashlights according to the requirements. Optimizing flashlight circuit diagrams can enhance performance, stability, and lifespan. We hope this article helps you further comprehend and build flashlights.